Our seasoned design and engineering innovators can take your idea for a product and develop your concept, implement it, prototype it and produce it. If you have a bottleneck within your manufacturing process, we can get to the real root of your problem and solve it with innovative, real-world design, engineering that leads directly to zero-defect manufacturing.

Our state-of-the-art design capabilities include:

- Concept development and validation

- Rapid prototype development and manufacturing – short and long run

- Design implementation

- Detailed and costed bills of materials

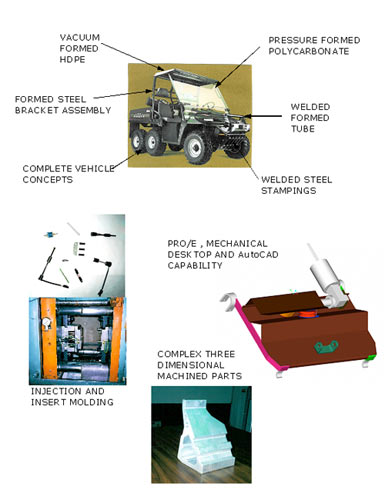

- Complete CAD – Pro/E 2000i2, Mechanical Desktop 4.0, and AutoCAD

- Structural analysis

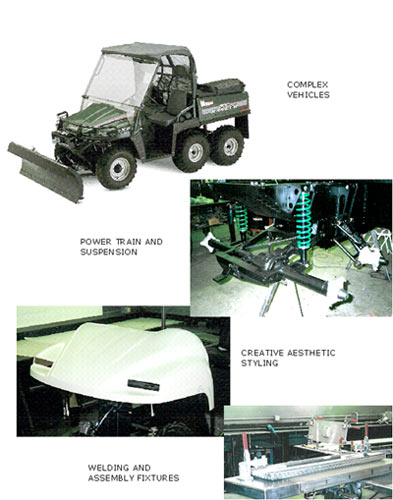

- Power train design

- Injection and insert molding part and tooling design

- Production fixturing, machine automation, and test equipment design

- Welding and cutting fixture design

- Vacuum form tooling design

- Programmable logic control systems and data acquisition

- Complete modeling shop – Lathes, Break Press, Shear, Hydraulic Press, End Mills, Drill Presses, Cut off Saw, Iron Worker, Tube Bender, Plasma Cutter, Welders, Fiberglass fabrication materials and Quality Control gauges and tools

- Experience in a broad range of vehicle and accessory development including manufacturing considerations for successful production startup

- Life cycle testing

- Video sales, audio sales, layout, editing of short ads, digital photography

Learn more about:

- Manufacturing Capabilities – serial manufacturing, injection molding, sheet metal and metal working and much more!

- Innovative Products —from atv’s, to moving wind turbine blades, to specialized oil field equipment.

- Specialized Manufacturing Projects – barbershop kiosks, BPO trailers, military ATVs, firefighting package and much more!